Solar panels have come a long way from the early days of basic silicon cells. Today, the cutting edge of photovoltaic technology includes ABC solar modules, a new type of panel that promises higher efficiency and better durability while maintaining a sleek appearance.

ABC stands for All Back Contact, meaning all the electrical contacts of each solar cell are moved to the rear side of the cell. By eliminating the metal lines on the front of the cell, ABC modules maximize the light-harvesting surface and eliminate front-side shading.

This innovation isn’t just for engineers and scientists – it’s being marketed to homeowners as the next leap in solar panel performance and aesthetics.

In this blog, we’ll go through ABC solar module technology, explain how it differs from conventional PERC or TOPCon panels, and discuss its structure, materials, efficiency, and reliability.

What Are ABC Solar Modules?

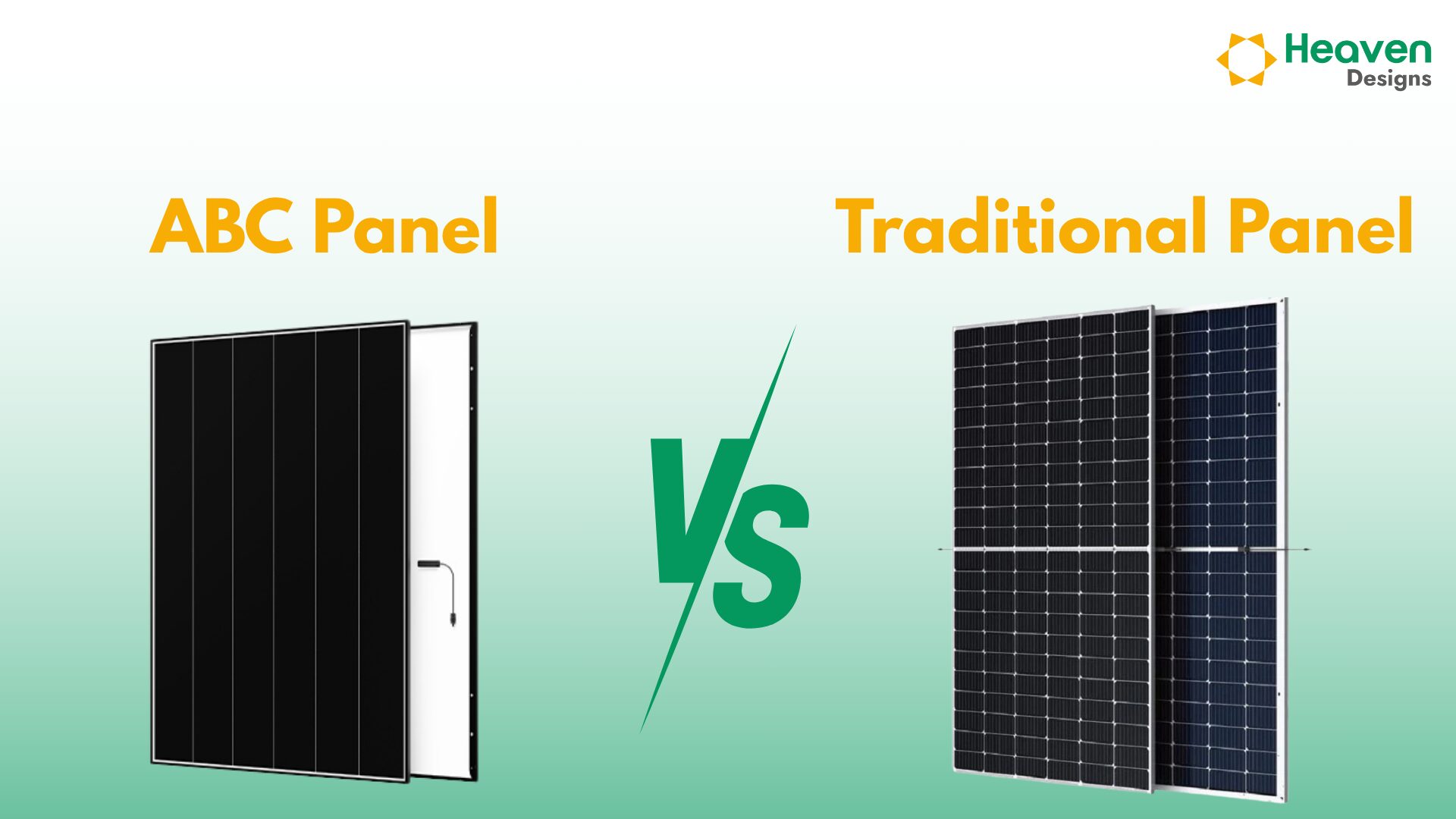

ABC solar modules are built with solar cells that have all their electrical contacts on the backside of the cell rather than on the front. In a conventional solar cell, you can see thin silver busbars or gridlines crisscrossing the front.

These metal contacts collect current but block a portion of incoming sunlight (typically 3–5% of the light). ABC technology removes those front wires entirely. Both the positive and negative terminals of each cell are interdigitated (arranged in alternating fingers) on the backside.

This back-contact design was first explored in laboratory research in the 1970s; however, it was only in the last decade that manufacturers refined it for mass production.

In practical terms, an ABC solar cell works similarly to the high-efficiency IBC (Interdigitated Back Contact) cells used by companies like SunPower (Maxeon). The front surface of the cell is entirely free of metallization, which means when sunlight hits the panel, 100% of the cell’s silicon area is active for light absorption.

Metal strips don’t block photons, so more light is converted into electricity. Meanwhile, the electrons and holes generated by light are collected by intricate finger-like contacts on the rear of the cell.

Advanced laser patterning and doping techniques create those alternating p-type and n-type regions on the back, allowing the cell to funnel charge carriers to the correct contact with minimal resistance.

In essence, ABC is a refined form of back-contact solar cell that integrates passivated contacts (low-recombination contact layers) with an interdigitated back grid. This integration maintains low electrical resistance while enhancing efficiency.

What Makes ABC Solar Modules Technically Unique?

ABC (All Back Contact) solar modules represent a significant advancement in solar cell architecture, combining superior efficiency, refined aesthetics, and robust material design. Unlike conventional technologies like PERC and TOPCon, ABC modules are constructed on n-type silicon wafers, which are inherently more resistant to light-induced degradation and exhibit better long-term stability.

The biggest difference lies in the placement of electrical contacts. In PERC and TOPCon cells, the front of the cell features silver gridlines (busbars) that collect current but block a small portion of sunlight. In contrast, ABC solar cells eliminate front-side metal entirely—all contacts (both positive and negative) are moved to the rear in an interdigitated pattern.

This unobstructed front surface enables maximum light absorption, thereby contributing to higher energy conversion efficiency.

Structurally, ABC cells use advanced passivating contact layers on both polarities, which are carefully doped and layered at the back of the cell. This design reduces electron recombination and enhances carrier collection, leading to higher efficiency and lower resistance losses.

While PERC uses a simple passivated rear and TOPCon adds a tunnel oxide layer to improve rear contacts, ABC takes it a step further by fully optimizing the entire rear surface.

Material-wise, ABC technology also moves away from silver—a costly and limited resource—by adopting copper-based metallization, which reduces production costs and environmental impact.

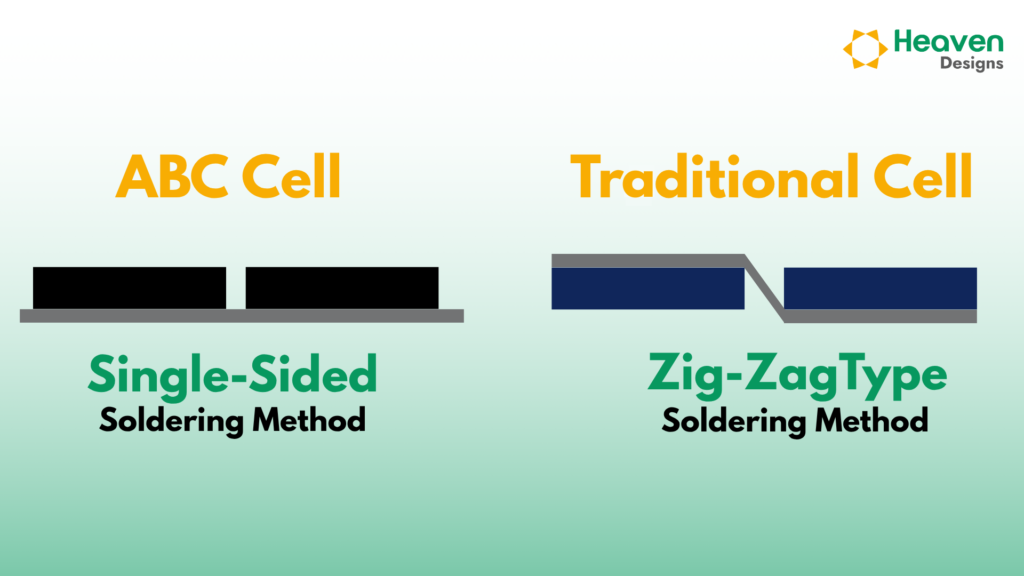

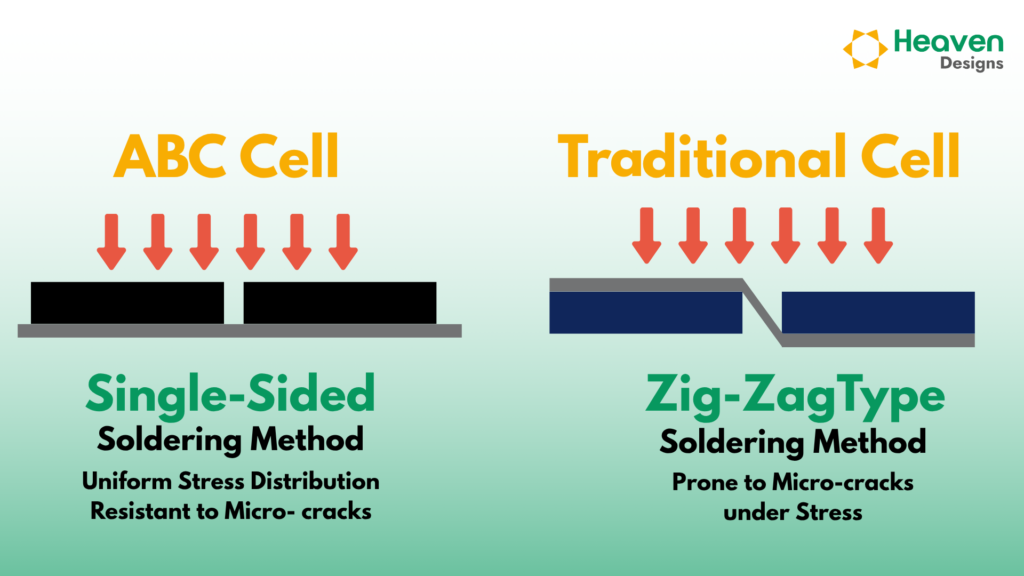

Additionally, the single-sided soldering method used in ABC modules simplifies the manufacturing process. It improves reliability by reducing mechanical stress compared to the zig-zag soldering method used in traditional modules.

ABC vs PERC vs TOPCon Solar Modules

In summary, ABC solar modules outperform PERC and TOPCon in multiple ways:

- Higher efficiency: With no front-side busbars, ABC cells can convert more sunlight into electricity. Homeowners can expect approximately 8–10% more energy output per year from an ABC panel compared to a similar wattage PERC.

- Partial Shading Resilience: A unique advantage in Aiko’s ABC design is a built-in “partial shading optimization” that allows individual shaded cells to be bypassed without knocking out an entire cell string. You can learn more from this video by Aiko

- High Temperature and Environmental Tolerance: The low-temperature coefficient (-0.26%/°C) means ABC panels handle heat better, which indirectly benefits longevity (less thermal stress per degree of heating). Many ABC modules are also offered in dual-glass configurations (glass-glass sandwich,) which improves moisture resistance and fire safety for the module.

- Lower Degradation Rates: Manufacturers of ABC panels typically offer 30-year performance warranties, which is longer than the standard 25 years for most conventional panels. After the first year, the drop is limited to ~1% for ABC. By comparison, a standard PERC panel might degrade by 2% in the first year due to LID/LETID effects and ~0.5% each year thereafter, ultimately reaching a power level of 80–82% of its initial power after 25 years.

This blend of technical sophistication and practical advantages makes ABC modules a powerful choice for both premium home systems and commercial applications aiming for long-term performance and aesthetics.

Also read: Bifacial Solar Panels Explained: All You Need to Know

Conclusion

ABC solar modules represent a significant step forward in photovoltaic technology, marrying the needs of engineers (high efficiency, advanced design) with the desires of homeowners (attractive looks, more power from limited roof space).

By relocating all cell contacts to the back, ABC panels eliminate front-side losses and offer a suite of advantages: higher energy output, improved performance in varied conditions, and robust long-term reliability.

Early leaders like Aiko Solar have demonstrated that this technology can be mass-produced – their panels are already hitting record efficiencies and performing in the field.

Compared to conventional PERC panels or other n-type panels, ABC modules offer a compelling combination of performance and longevity, albeit at a currently premium price.

As the solar industry continues to innovate, all-back-contact designs are poised to play a big role in the next generation of solar installations, from residential rooftops to commercial solar farms.

With further improvements and broader adoption, homeowners and businesses alike can look forward to solar panels that produce more energy, last longer, and look better doing it – truly a win-win for the solar revolution.