It can be difficult to decide on the best solar panel for your situation, especially when you consider the different options available in the current market. One of them is choosing the type of Solar Cells.

Solar cells are most commonly of two types: half-cut solar cells and full-cut solar cells. Both have their own advantages, but knowing which technology is used where and how it performs in real-world scenarios can help you choose better.

In this blog, we will cover the unique aspects of half-cut and full-cut solar cells in terms of efficiency, longevity, and cost-effectiveness, as well as their specific performance effect with different installation settings. We will analyze what differentiates these two technologies and which one is suitable for your solar requirements.

What Are Full-Cut Solar Cells?

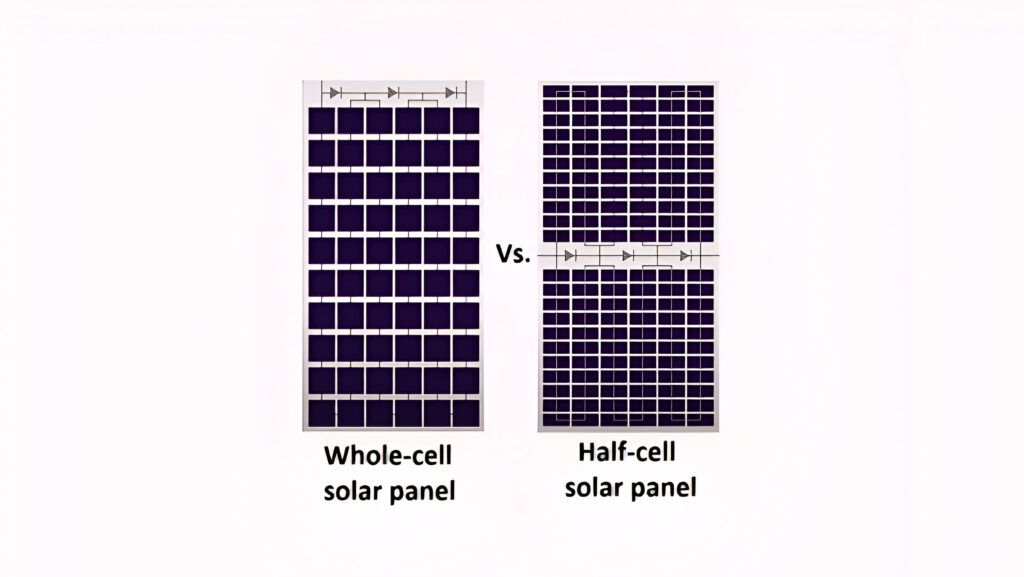

Full-cut cells are the traditional, standard type of solar cell, where each cell is a single, intact piece. These cells have been the backbone of solar panels for decades and are well-known for their cost-efficiency.

Full-cut cell panels consist of uncut silicon wafers wired together in series to form a module. This type of solar cell costs slightly less due to simpler manufacturing and fewer components.

However, full-cut cells have certain limitations, especially in terms of shading and heat performance. When partially shaded, full-cut cells experience a significant reduction in energy output, as shading on one cell affects the entire series.

What Are Half-Cut Solar Cells?

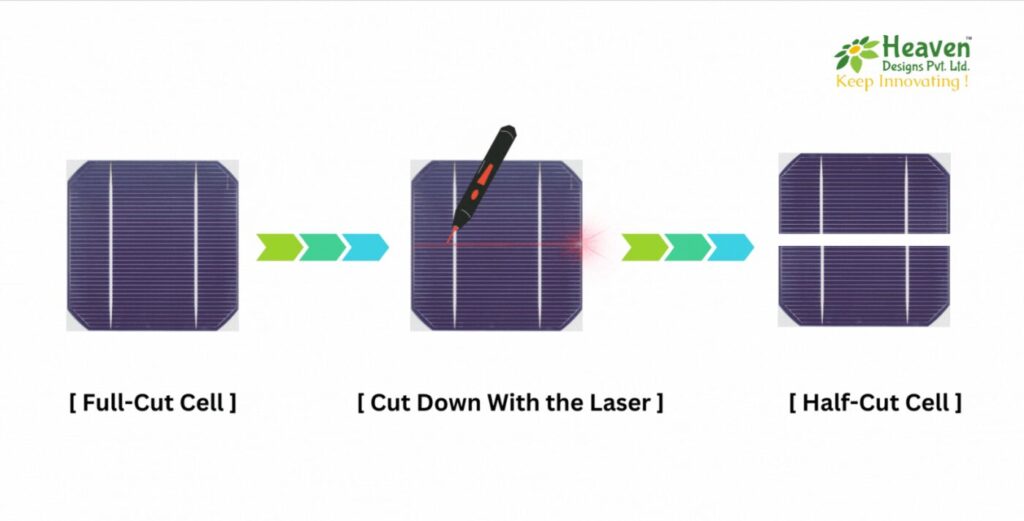

Half-cut solar cells are an advanced technology that improves the traditional full-cut design. In half-cut panels, each full solar cell is split into two smaller cells, just like cutting bread slices into two equal pieces.

These smaller cells are wired together. Splitting the cells reduces the electrical resistance, allowing for more efficient energy flow. This produces higher energy output than full-cut cells, especially in partially shaded conditions.

In-depth Technical Comparison of Half-Cut & Full-Cut Solar Cells

Energy Efficiency

Half-cut cells are known for their higher efficiency. The splitting of the cells reduces resistive losses within the panel, allowing more electricity to be captured and used.

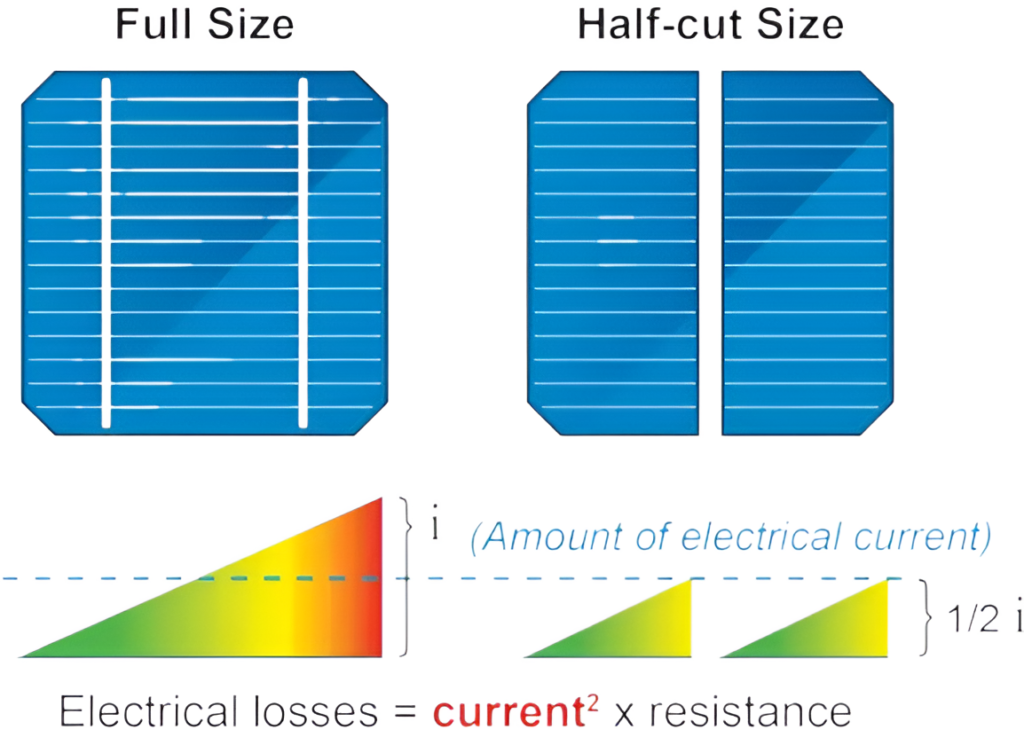

Full-cut cells, by contrast, suffer from higher resistive losses due to the larger size of each individual cell. The process involves cleaving a processed cell in half and is based on the logic that each maintains the same voltage output but produces half the current. This reduction in current significantly lowers resistive losses, as shown by the equation Ploss = I^2R, where resistive losses are directly proportional to the square of the current. The resistive losses are reduced by around 75% by halving the current.

Consequently, half-cell modules are designed to look like two smaller modules connected in parallel, optimizing performance by minimizing energy loss.

Shading and Hotspot Performance

Shading can significantly affect solar panel output. In traditional full-cut cells, even minor shading can drop the panel’s output to zero, as the cells are connected in series. Hotspots caused by shading can also create long-term damage, reducing the panel’s lifespan.

Half-cut cells mitigate this issue by using parallel connections, which means that if one section of the panel is shaded, the rest can still function optimally. Additionally, because half-cut cells handle lower current, they reduce the risk of hotspots, which is a common issue in traditional full-cut panels

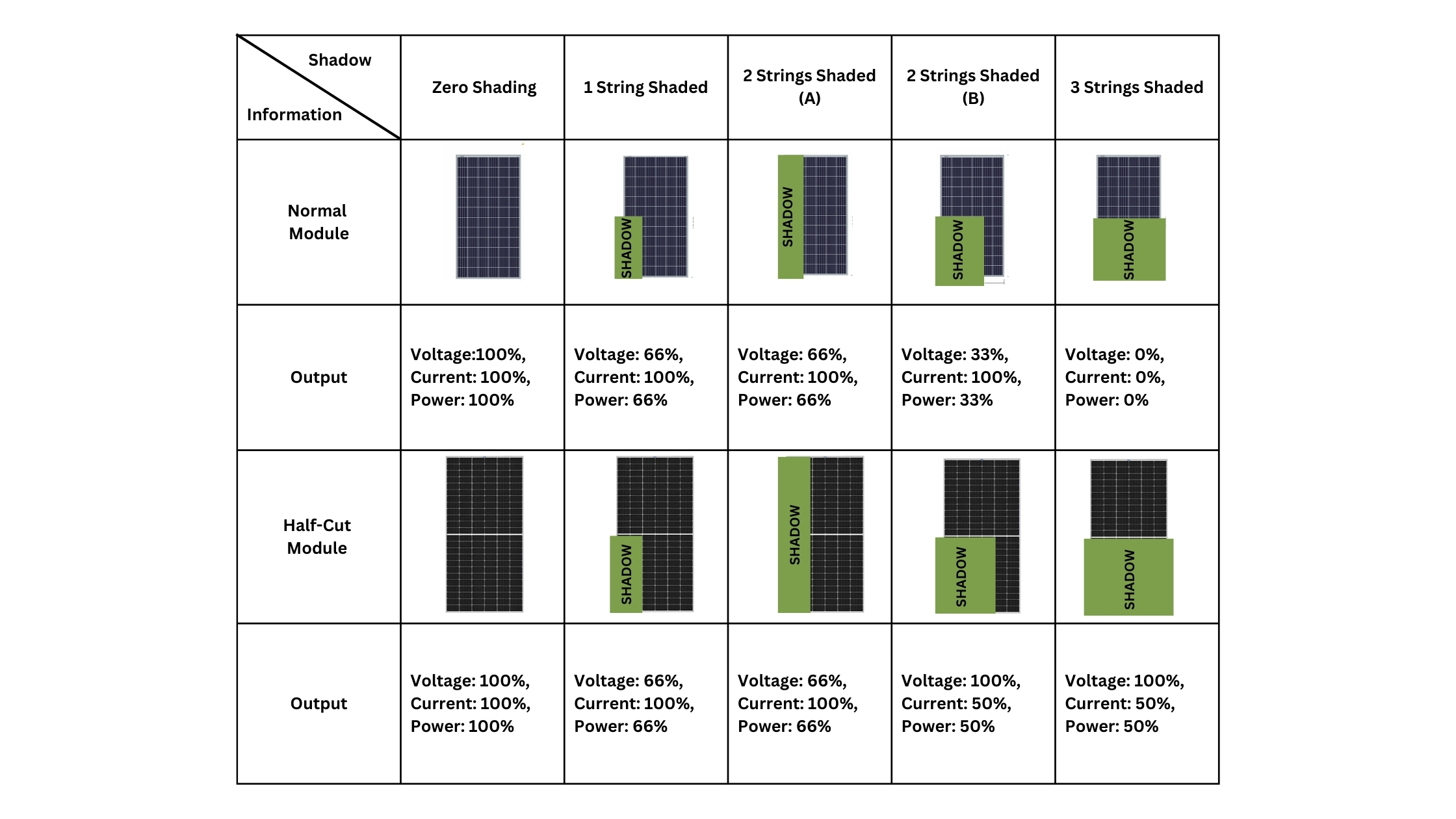

The illustration below shows how the current (A), voltage (V), and power (Wp) of half-cut and full-cut solar panels change under different shading conditions.

Durability and Longevity

Due to their design, half-cut cells are more durable. The smaller, more compact cells are less prone to mechanical stress and microcracks, which can degrade traditional full-cut cells over time. Moreover, since half-cut cells generate less heat, they experience less thermal stress, extending their operational lifespan.

A test in high-temperature environments revealed that half-cut panels maintain their efficiency longer than full-cut cells due to better heat management and lower internal resistance.

Applications in Advanced Solar Installations

Half-cut solar technology is increasingly being integrated into advanced solar systems such as bifacial solar panels and agrivoltaics. These systems rely on maximizing energy output, often in challenging environments where shading, heat, and panel elevation play significant roles.

- Agrivoltaics: In agricultural settings where partial shading from crops is inevitable, half-cut cells can ensure energy production continues uninterrupted. This is particularly important for systems designed to work with fluctuating environmental conditions.

- Bifacial Panels: Half-cut technology is also common in bifacial panels, where the panel’s front and back sides collect sunlight. The enhanced shading tolerance and efficiency of half-cut cells make them ideal for installations with variable light conditions

Conclusion: Which Should You Choose?

When comparing half-cut and full-cut solar cells, the right choice depends on your specific project needs. Full-cut cells offer a cost-effective solution for homeowners and businesses with smaller budgets or less demanding energy requirements.

However, half-cut cells are the superior option if your goal is to maximize energy production, particularly in shaded areas or challenging weather conditions. Their higher efficiency, enhanced shading performance, and improved durability make them a worthwhile investment for long-term energy generation.

Ultimately, by considering factors such as installation environment, shading, and energy needs, you can choose the solar technology that delivers the best return on investment for your system. Both options have their place in the solar industry, and the decision should align with your project’s priorities and budget.