Welcome to a detailed step-by-step guide to Component A, covering eligibility, land requirements, application process, PPA, and expert insights for setting up decentralized solar plants.

Eligibility Check

1. Who can apply?

- Farmers (individual or group).

- Farmer Producer Organizations (FPOs).

- Cooperatives, Water User Associations (WUAs), and Panchayats.

- Companies or entrepreneurs with an agreement to utilize agricultural land for solar projects.

2. Land Requirement

- Barren/ Fallow/Marshy/ Pasture or Cultivable land. All types of land are eligible.

- Sufficient for the desired capacity (approximately 4–5 acres per MW of solar plant).

- The land must be within 5 km of a grid substation to ensure connection feasibility and reduce transmission losses.

3. Documents Required

- Aadhaar card

- Proof of land ownership, eg.For Gujarat 7/12

Things to Know Before Starting

1. Land Requirements

- Approximately 4–5 acres of land per MW capacity.

- Eligible land types include barren, fallow, marshy, pasture, or cultivable land.

- The land should ideally be located within a 5 km radius of a grid substation to minimize transmission losses and reduce sub-transmission line costs.

2. Ownership and Leasing

- Farmers can directly use their own land or lease it to developers.

- A model land lease agreement is available, and terms such as lease rent (e.g., Rs. per acre per year or Rs. per unit energy generated) can be mutually agreed upon between the landowner and the Renewable Power Generator (RPG).

- Lease payments can be directly credited to the farmer’s bank account.

3. Substation Capacity

- Check the available capacity at the nearest substation (33/11 kV, 66/11 kV, or 110/11 kV) to ensure grid connectivity.

- DISCOMs publish substation-wise capacities on their websites to guide applicants.

4. Tariff and Revenue

- DISCOMs will purchase power from these renewable energy projects at a pre-fixed levelized tariff.

- In case the total applications exceed the notified substation capacity, bidding will determine the final tariff, capped at the pre-fixed levelized rate.

5. Transmission Line Responsibility:

You may need to bear the costs of connecting your project to the substation. This includes the cost for 11 or 33KV, 66/11KV, or 110/11KV lines from the Renewable Energy Power Plant to the substation, the construction bay, and related switchgear at the substation where the plant is going to be connected.

6. Bank Guarantees and Penalties:

- An Earnest Money Deposit (EMD) of Rs. 1 Lakh/MW is required during the application process.

- Selected applicants must convert EMD into a Performance Bank Guarantee (PBG), which will be returned upon successful commissioning of the project.

- Delays in commissioning may result in penalties, including encashment of the PBG.

7. Clearances and Approvals:

- Obtain necessary clearances from state and local authorities, such as land and right-of-way permissions.

- DISCOMs and District Collectors assist in facilitating these approvals.

Step-by-Step Guide for PM-KUSUM Project (Component A)

Application Process

Application Process varies state by state. To check your state flow process, visit here https://pmkusum.mnre.gov.in/#/landing/more-about-A

The application is chargeable and non-refundable; the fee is Rs. 5000/-per MW.

If the total capacity requested by all the applicants for a specific substation is less than or equal to the capacity available at that substation (as announced by the DISCOMs), A Letter of Award (LoA) will be given to eligible applicants. This letter allows them to sell renewable energy at a pre-decided fixed tariff. The awards will be given on a first-come, first-served basis within one month of receiving the applications.

If the total capacity requested by all the applicants for a specific substation is more than the capacity available at that substation, then DISCOMS invites all the applicants to bid.

Bidding

- Closed Bid: Where all bidders submit their tariff quotes, and the lowest one is chosen.

- E-Reverse Auction: An online process where bidders compete by reducing their tariffs until the lowest one wins.

- All eligible applicants must submit their price bids within a given time. The bidder with the lowest price will be selected first, then the next lowest, and so on. Once the selection is made, all successful bidders will receive a Letter of Award (LoA).

- As an RPG, you’ll need to submit an Earnest Money Deposit (EMD) of Rs. 1 Lakh per MW in the form of a Bank Guarantee and your Expression of Interest (EOI). Just a heads-up – if you decide to withdraw your application after placing your bid, this amount will be charged as a penalty.

- The EMD of Rs. 1 Lakh per MW you submit will be turned into a Performance Bank Guarantee (PBG) if you’re a successful bidder and sign the Power Purchase Agreement (PPA) within the given time.

- If you fail to sign the PPA within the stipulated time, the EMD Bank Guarantee will be cashed by the DISCOM as a penalty.

- If you’re not selected, DISCOM will release your EMD within 15 days of issuing the Letter of Award (LoA) to the selected RPG(s).

- The PBG will be valid for 15 months from the date the LoA is issued.

Finally, once the REPP (Renewable Energy Power Plant) is successfully commissioned, the PBG will be returned to you, considering any penalties for delays as per the guidelines.

Power Purchase Agreement (PPA)

- The model PPA between you (the RPG) and the DISCOM is provided in Annexure II.

- The PPA will last 25 years, starting from your project’s Commercial Operation Date (COD).

- As the RPG, you must sign the PPA within two months from the Letter of Award (LoA) being issued by the DISCOM or an authorized agency.

- The DISCOM is required to buy all the power your plant generates up to the agreed contract capacity.

- After the 25-year PPA period ends, you can continue operating your plant as long as other conditions (like land lease) allow.

- If you and the DISCOM agree, you can extend the PPA beyond 25 years.

- The DISCOM must set up an Escrow Arrangement to ensure payment security, as stated in the PPA.

Important Note :

As per the guidelines by Bharat Sarkar, achieving a Capacity Utilization Factor (CUF) of at least 19% for two months is required to get up to 100% of the Central Financial Assistance (CFA) under PM-KUSUM Yojana.

Also, maintaining CUF ≥ 19% over the 25-year lifetime of a plant without deration is crucial for better Return On Investment (ROI).

Ensuring and maintaining this CUF requires attention to four key factors:

- Site Assessment (Pre-Execution)

- Design Optimization (Pre-Execution)

- Regular Maintenance (Post-Execution)

- Performance Monitoring (Post-Execution)

At Heaven Designs, we specialize in Site Assessment and Design Optimization, two critical components of the Pre-Execution stage, which lay the foundation for long-term project success.

Pre-Execution Stage

1. Site Assessment

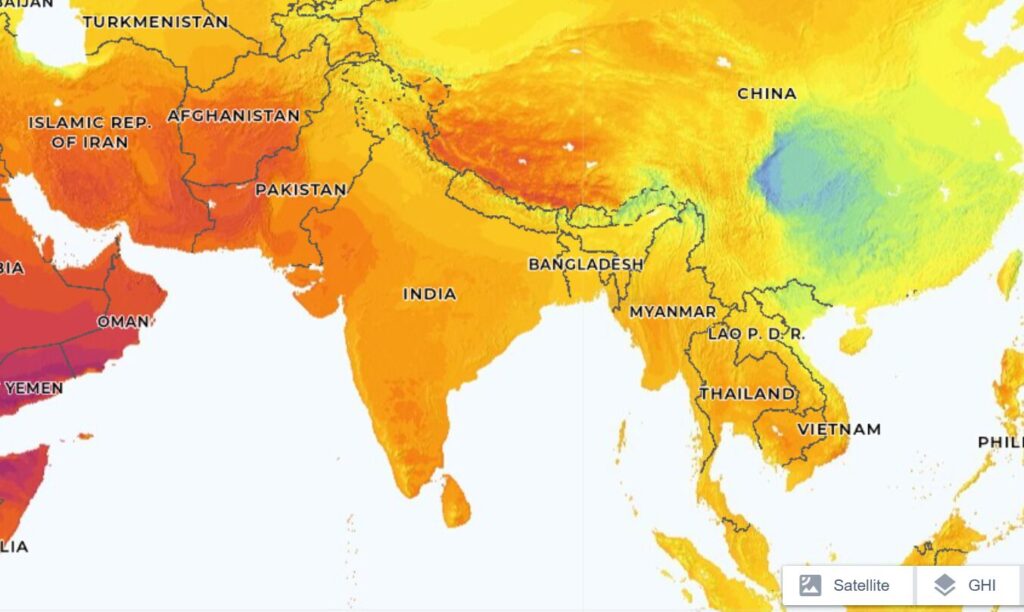

I) Solar Irradiance Measurement

Using tools like pyranometers or satellite data to measure Global Horizontal Irradiance (GHI), Direct Normal Irradiance (DNI), and Diffuse Horizontal Irradiance (DHI). This helps to analyze the historical solar data so that we can accurately estimate the energy production potential of the site, which enables better project planning.

II) Land Assessment

When planning a solar power plant, it’s vital to ensure you have enough land—typically 4-5 acres per MW for ground-mounted systems. But it’s not just about the size; the land’s features matter, too! Checking slopes and elevations helps avoid costly leveling work, and soil tests ensure the foundations are strong and durable. Identifying shadow-casting obstructions, like trees, buildings, poles, etc., helps build shadow-free plants.

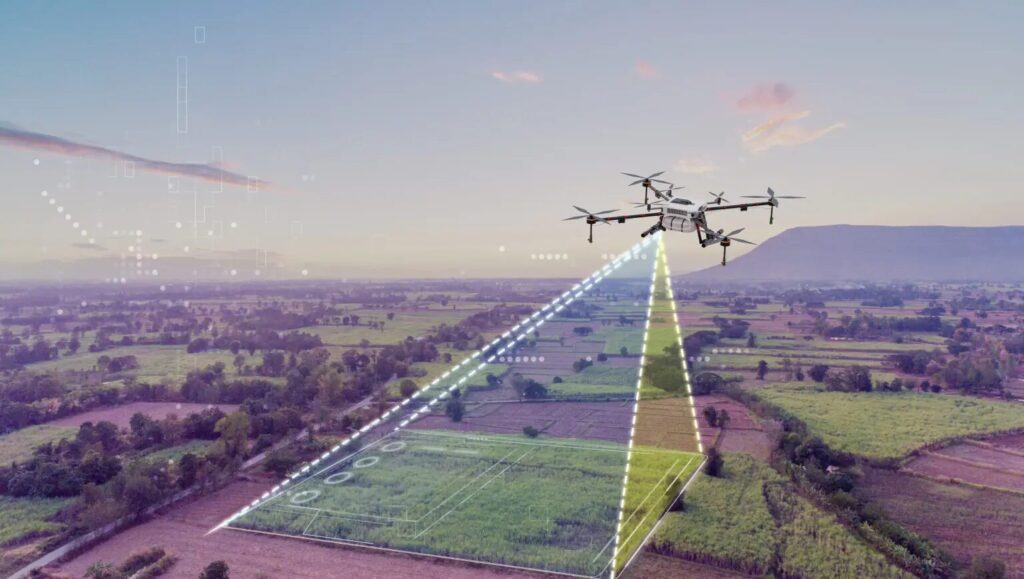

It is important to complete the project within the given time frame to avoid penalties. With a focus on accuracy and efficiency, we recommend and provide drone-based land assessment services.

These advanced surveys can be completed in as little as 30 minutes (depending on the site’s size and complexity). High-resolution images captured by drones provide precise details, enabling the creation of ultra-detailed 3D models. Additionally, the ability to export 3D models directly into CAD formats like DXF streamlines the design process, reducing the time needed to finalize layouts by up to 50%.

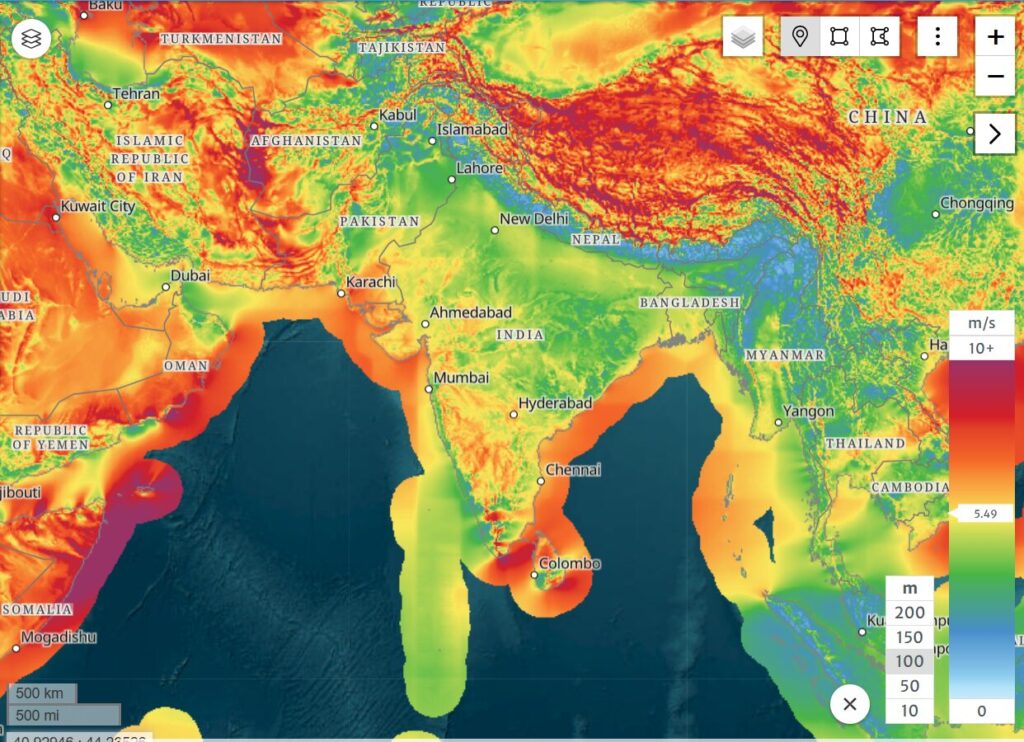

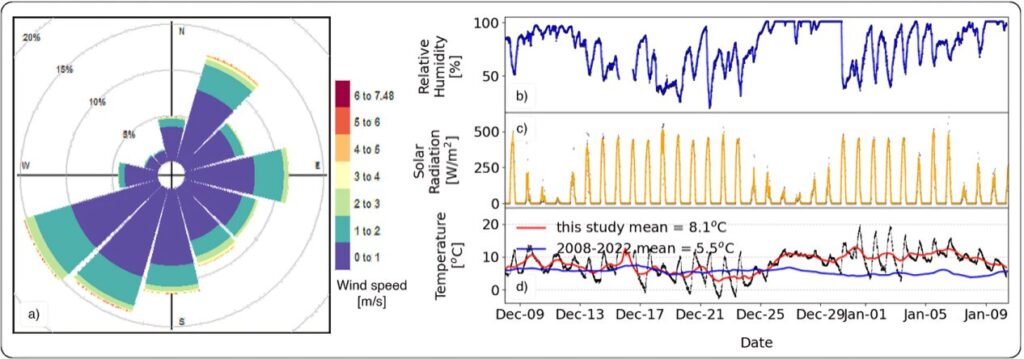

III) Climatic and Weather Assessment

When you’re signing a Power Purchase Agreement (PPA) for 25 years, the stability of your solar power plant becomes a top priority. To make the plant truly future-proof, your power plant should prepared, whether it’s heavy rainfall, snowfall, or even flood risks.

At Heaven Designs, we handle all key aspects of climate assessments to ensure your solar power plant is future-proof. We analyze temperature variations to address efficiency losses, assess wind speeds to design robust structures, and study rainfall and snowfall patterns to create effective drainage systems and cleaning plans. Additionally, we evaluate flood risks to protect ground-mounted systems. With our expertise, your plant will be resilient, efficient, and prepared to deliver consistent performance under any environmental conditions, built to last, no matter the weather.

With the expertise of 1000+ MW design and The data that is carried out during the site assessment now, it will now help with Design optimization.

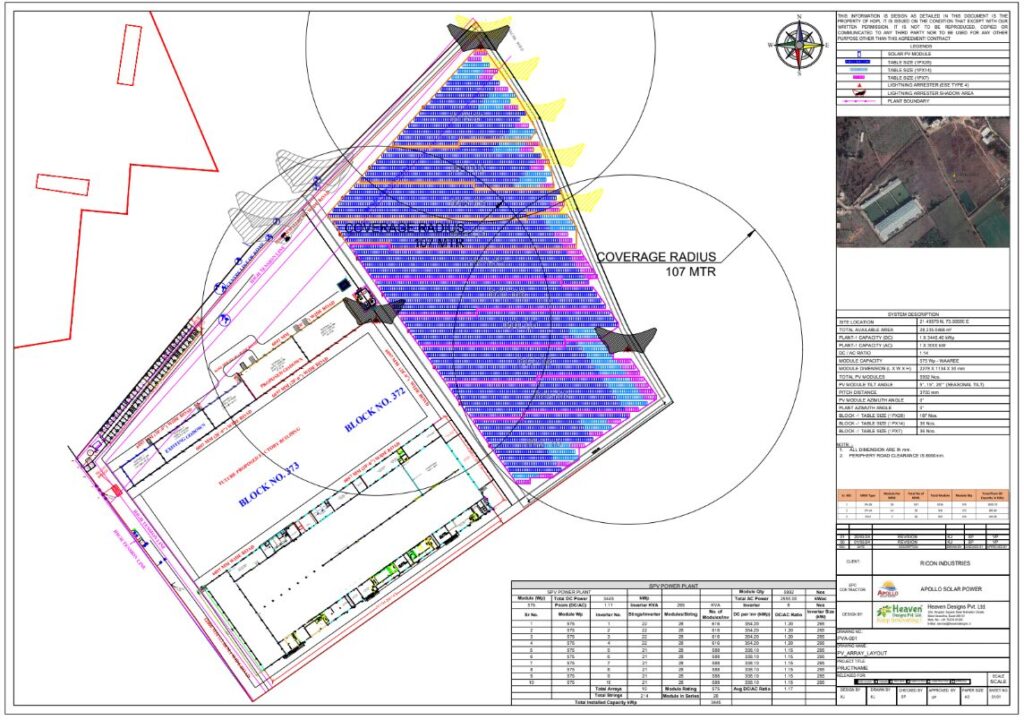

2. Design Optimization

I) Pre-Design Stage

The Pre-Design stage focuses on leveraging data from the Site Assessment to create foundational layouts and validate the feasibility of the solar power plant.

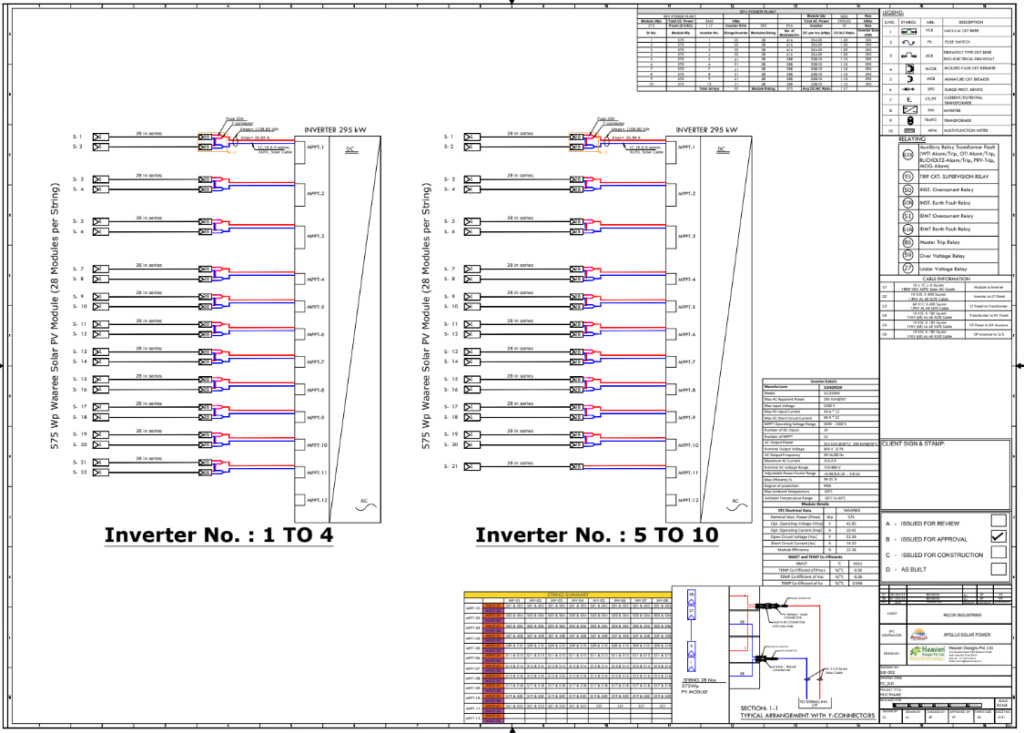

- Data Utilization for String Design:

The temperature data collected during the Site Assessment plays a critical role in designing solar PV strings. PV module strings are designed to account for temperature variations using the module’s temperature coefficient. This ensures that the Maximum Power Point Tracking (MPPT) system operates efficiently. This guarantees maximum energy efficiency even in the harshest environments. - General Arrangement (GA) Layout:

The General Arrangement (GA) layout, created using BricsCAD, is like the blueprint for the solar power plant. It helps us map out the plant while keeping the design shadow-free and maintaining the right pitch distance and inter-row spacing. This ensures the solar modules are arranged optimally to capture the most sunlight and make the best use of the available space. - Preliminary 3D Design in SketchUp:

At the same time, we create a 3D design in SketchUp to give stakeholders a clear, realistic idea of how the plant will look. This design isn’t just for visuals—it plays a crucial role in generating a tentative PVsyst report. The report provides valuable insights into the plant’s energy generation potential and checks if the design is feasible for the location. Plus, it helps us decide whether a fixed tilt, seasonal tilt, or tracker system would work best for the site. This way, we can choose the most efficient option for the plant’s specific needs.

II) Post-Design Stage

The post-design stage is about taking the initial plans and turning them into a fully refined and finalized design ready for execution. Here’s how we ensure your solar power plant is both structurally sound and operationally efficient:

- Mounting Structure System (MMS):

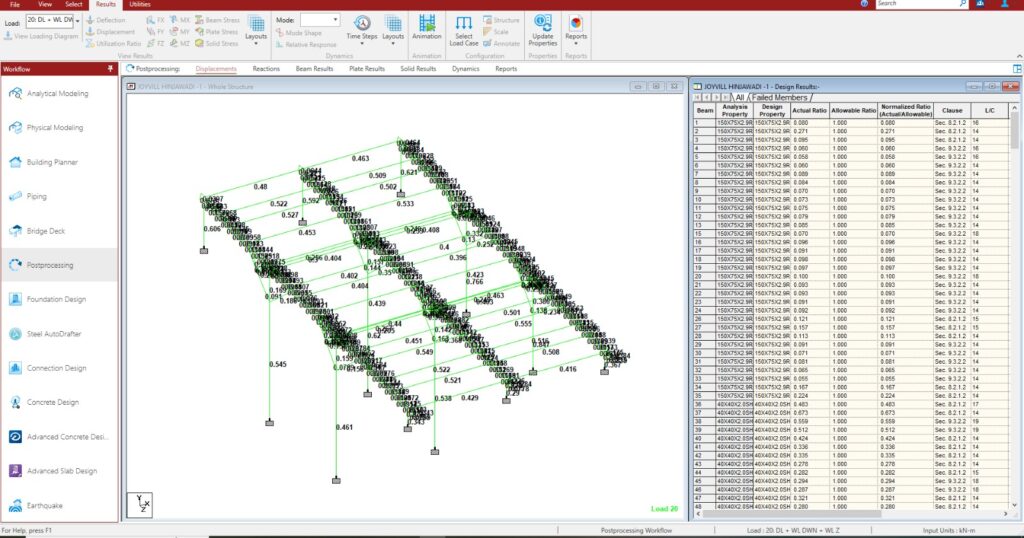

Once we have the Soil Bearing Capacity (SBC) reports, we can determine the most suitable foundation type for the site. We decide whether to use helical piles, earth-screws, ballasted foundations, or driven piles, depending on the soil conditions. This ensures the mounting structures are stable, durable, and perfectly tailored to the site’s requirements. Additionally, we calculate the optimal tilt angle to maximize sunlight capture and energy production, building a foundation that’s as efficient as it is robust. - Structural Feasibility Analysis:

We analyze the finalized layout using STAAD Pro to guarantee the design’s structural integrity. This step verifies the plant’s ability to withstand environmental challenges like wind loads, seismic activity, and other site-specific factors. Combined with the foundation type chosen based on the SBC report, one of the most critical aspects of this service is the assurance that your solar power plant won’t become a “flying kite” during high wind events. Heaven Designs provides this essential analysis to give you peace of mind that your investment is built to last and future-proof for its 25-year operational lifespan.

- Detailed Electrical Design:

The final step involves creating Single Line Diagrams (SLDs), optimizing cable sizing, and configuring protection systems and inverter placement. This ensures minimal energy losses and high operational safety.

Our electrical design covers:

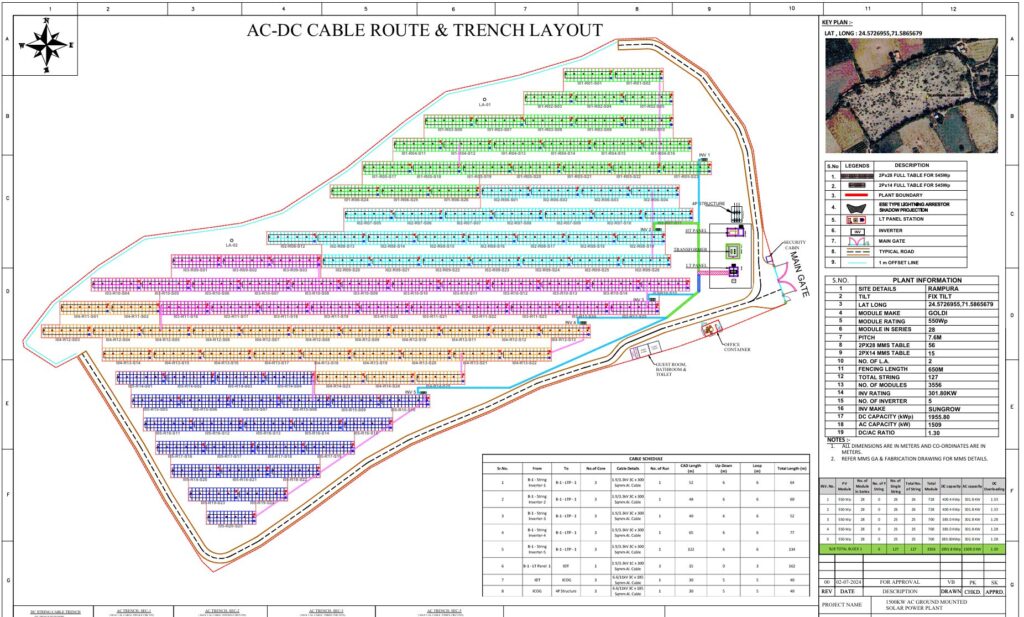

- Single Line Diagram (SLD): Developing clear, detailed diagrams to outline electrical connections and system flow.

- AC/DC Cable Sizing: Calculating the appropriate cable sizes to handle the expected current while minimizing losses and ensuring safety.

- DC/AC Voltage Drop Calculation: Ensuring voltage drops are kept within permissible limits to maintain system efficiency.

- Cable Layout Using Optimized Methods: Strategically designing cable routes to minimize lengths and costs while maximizing performance.

- Cable Trench Layout: Planning and designing cable trenches for safe and efficient cable installation.

- Earthing and Lightning Arrestor Layout: Designing a reliable earthing system and lightning protection layout to safeguard the plant and personnel from electrical hazards.

- HT Side and LT Side Designing: Creating detailed designs for both High Tension (HT) and Low Tension (LT) sides to ensure seamless power transmission and distribution.

Post-Execution Stage

After successfully installing and commissioning a solar power plant, Heaven Designs strongly recommends focusing on these two key aspects: Regular Maintenance and Performance Monitoring.

1. Regular Maintenance

- Cleaning of Solar Panels: Solar module cleaning at least twice a month is recommended for solar power plants for good output.

- Inspection of Components: Routine checks of inverters, cables, mounting structures, and junction boxes to identify and resolve any wear or damage.

- Preventive Maintenance: Proactive measures like tightening electrical connections, checking for corrosion, and ensuring proper functioning of protection systems like earthing and lightning arrestors.

2. Performance Monitoring

- Real-Time Data Monitoring: Using advanced monitoring systems to track energy generation, module temperatures, and inverter performance.

- Analysis of Key Performance Indicators (KPIs): Evaluating metrics like CUF, PR (Performance Ratio), and downtime to measure the plant’s operational efficiency.

- Alerts and Fault Detection: Automated alerts for issues like string failures, inverter faults, or unusual energy drops to ensure immediate resolution.

Part of the Article is taken from https://heavendesigns.in/pm-kusum-component-c-explained/

Reference Link: https://cdnbbsr.s3waas.gov.in/s3716e1b8c6cd17b771da77391355749f3/uploads/2024/01/20240118413909461.pdf